HIGHLIGHTS

- A total of 260 out of 619 health service points (42 per cent) across the Gaza Strip are functioning, 90 per cent of them partially. All hospitals in Gaza remain fully dependent on back-up generators, with delays in the entry of related spare parts, uninterruptible power supply (UPS) systems, transformers and critical electrical components impacting Intensive Care Unit, dialysis, operating theatre and laboratory functionality.

- Between 11 and 23 February, around 2,500 cubic metres of accumulated waste had been relocated from Firas Market to the newly identified temporary dump site in Abu Jarad. Newly generated waste from Gaza city and North Gaza is now being sent directly to Abu Jarad.

- Nine more Women and Girls’ Safe Spaces were established in Gaza city, Deir al Balah and Khan Younis during the reporting period, bringing the total to 68 across the Strip.

- Between 18 and 24 February, Cash Working Group partners distributed multi purpose cash assistance to more than 3,500 households across the Gaza Strip through digital payment modalities.

SITUATION OVERVIEW

Between 20 and 25 February, airstrikes, shelling and gunfire continued across the Gaza Strip, reportedly resulting in civilian casualties and damage to civilian infrastructure. According to the Ministry of Health in Gaza (MoH), seven Palestinians were killed, and 33 others injured during this period, bringing the total casualty toll reported by MoH since the ceasefire came into effect on 10 October 2025 to 618 killed and 1,663 injured.

Throughout the reporting period, the Rafah Crossing remained open for limited movement of people. Overall, since the crossing reopened in early February, WHO has facilitated the medical evacuation of 289 patients, alongside 521 caregivers. During the same time frame, the UN and humanitarian partners have also supported 804 returnees, providing them with protection, medical assistance, and transportation as well as basic supplies.

Efforts to address immediate weather‑ and accident‑related needs and provide critical services to underserved communities through joint humanitarian aid distributions continued during the reporting period. On 25 February, joint teams began distributing multi-sectoral assistance packages, comprising mostly shelter and hygiene items, to over 240 families affected by a rainstorm that struck Gaza between 23 and 24 February.

On 26 February, partners also distributed food assistance as well as shelter and hygiene items to over 400 families in the Bani Suhaila area of Khan Younis. The targeted families are residing in a hard-to-reach and underserved area and have experienced repeated displacement in recent months due to shifts of the “Yellow Line”.

According to the latest WFP Market Monitor, food consumption in Gaza continued to show encouraging signs of improvement in the first eleven days of February, sustaining the gains observed in January. While more accessible market prices and increased food availability have driven a noticeable recovery in food consumption patterns compared to pre‑ceasefire levels, significant gaps persist. Vegetables are still consumed on average two days per week, down from six before October 2023, while fruits are consumed just half a day per week, compared to three prior to October 2023. Protein (meat, poultry, eggs) consumption equally remains limited at one day per week, compared to three. Access to energy sources represents a persisting challenge, with over 50 per cent of the population still reporting relying on waste burning as an alternative to cooking gas in February. Encouragingly, however, in the northern governorates, the share of households able to use cooking gas reached 10 per cent, signaling gradual improvement.

On 11 February, OCHA, in coordination with operational partners, conducted a needs assessment of more than 1,800 families living in areas of Deir al Balah adjacent to the “Orange Line” where Israeli authorities recommend prior coordination for humanitarian movements. Field engagement with camp focal points from particularly underserved areas evidenced severely limited access to essential services. Priority needs include drinking water, food assistance, functioning water pumps, and emergency shelter solutions, such as dome tents, alongside key essential items like tarpaulins, kitchen kits, hygiene kits, and winter clothing. In response, a shelter partner is preparing targeted shelter materials and other essential items for these families. Additional underserved locations across the Strip will be also assessed.

HUMANITARIAN AID*

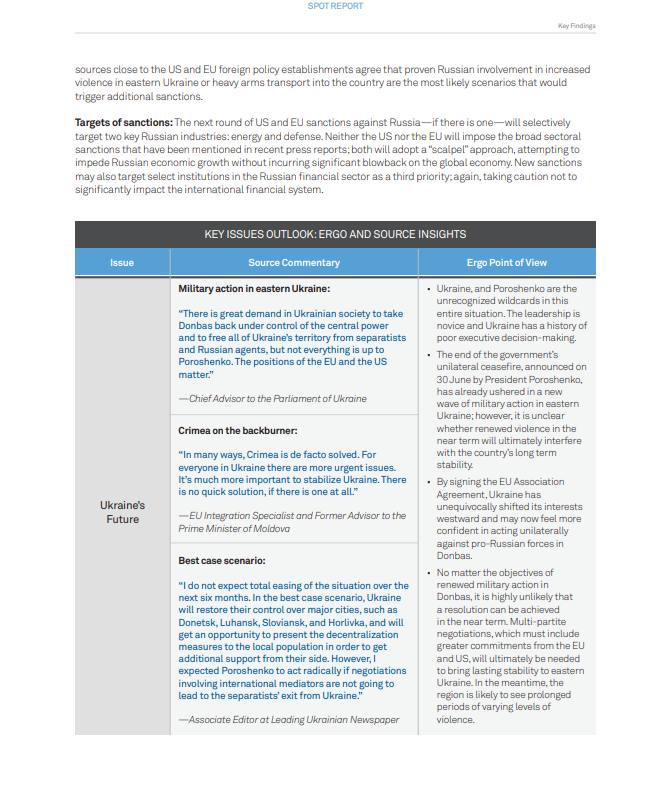

Between 20 and 26 February, based on data retrieved from the UN2720 Mechanism dashboard at 16:00 on 27 February, nearly 7,500 pallets of aid administered by the UN and partners were offloaded at Gaza’s crossings. About 66.5 per cent of these pallets contained food supplies, followed by shelter items (23 per cent), water, sanitation and hygiene (WASH) assistance (5.5 per cent), health items (2 per cent), as well as operations, logistics and telecommunication material, nutrition and other items (less than 3 per cent cumulatively).

During the same period, just above 7,200 pallets of aid were collected at Gaza’s crossing. About 82 per cent of these pallets contained food supplies, followed by shelter items (9 per cent), nutrition supplies (8 per cent), and health (less than one percent).

Overall, between the announcement of the ceasefire on 10 October 2025 and 26 February 2026, at least 309,428 pallets of humanitarian cargo were offloaded, and nearly 312,00 pallets were collected from the operating crossings. Some 1,532 pallets, less than one per cent of all collected aid, were intercepted during transit within Gaza.

The above data does not include bilateral donations and the commercial sector.

Between 20 and 26 February, the United Nations coordinated 55 humanitarian missions with the Israeli authorities inside Gaza. Of these, seven (13 per cent) were denied outright. Of the remaining missions, 32 (58 per cent) were facilitated, and 15 (27 per cent) were approved but faced impediments, including long delays. Of these, 11 missions were eventually fully accomplished, two only partially and another two failed. One mission was also cancelled by the organizers.

UN and international NGO trucks manifested through the Egypt Corridor continued to face low offload rates during the reporting period. Overall, between 18 and 24 February, out of 244 trucks manifested by the Logistics Cluster, only 72 — 30 per cent — offloaded at Kerem Shalom. Since the start of the month, only 34 per cent of all 1,098 trucks manifested by the Logistics Cluster through the Egypt Corridor have been offloaded.

HUMANITARIAN RESPONSE

Food Security

- As of 23 February, Food Security Sector (FSS) partners had reached approximately 200,000 families (about one million people) with household-level general food assistance as part of the monthly distribution cycle. Since 5 February, ration sizes have been covering half of the minimum caloric needs.

- As of 21 February, almost 1.73 million meals continued to be prepared and delivered daily by partners through 182 kitchens across Gaza – 565,000 meals through 54 kitchens in the northern governorates and 1.164 million meals through 128 kitchens in southern and central Gaza. Since the start of Ramadan, partners have adjusted cooked meal preparation and distribution timings to align with fasting hours. Partners also continue to enhance meal quality with additional fresh produce and/or protein products.

- As of 25 February, approximately 160,000 two-kilogram (kg) bread bundles were produced daily through 19 UN-supported bakeries. One third of this bread is distributed for free, along with cooked meals, to more than 400 shelters and community sites, while two thirds are sold through 143 retailers at a subsidized price of 3 NIS ($0.95) per bundle.

- If the current humanitarian aid truck offloading rates through the Egypt corridor continue to be low, the daily production of nearly one million meals, representing 55 per cent of all meals produced by humanitarian partners, as well as 300,000 loaves of bread, including the 13,000 meals and 32,000 loaves of bread delivered each day to health facilities across the Strip, is at risk of coming to a pause by early March. Humanitarian partners are working hard to bring in additional supplies during the last week of February to prevent any shutdown. For the March general food distribution cycle, partners may not have sufficient stock to sustain even the half-rations distributed since 5 February throughout the month.

Health

- As of 23 February, 260 of 619 health service points were functioning across the Gaza Strip, 90 per cent of them only partially. These include 19 out of 37 hospitals, 12 field hospitals, 106 primary health care centers, and 123 medical points. Geographically, the largest concentration of services is in Deir al Balah (91), followed by Khan Younis (77), Gaza governorate (79) and North Gaza (7). Additionally, 22 ambulance centers are partially functioning with 10 in Deir al Balah, nine in Khan Younis, two in Gaza city, and one in Rafah.

- All hospitals in Gaza remain fully dependent on emergency back-up generators. Dual-use restrictions continue to delay entry of generators/spare parts, uninterruptible power supply systems, transformers and critical electrical components, impacting Intensive Care Unit, dialysis, operating theatre and laboratory functionality.

- Between 18 and 24 February, seven medical evacuation missions were conducted, enabling 123 patients, along with 201 companions, to leave Gaza to receive urgent medical treatment unavailable in the Strip. Of all patients, 72 were trauma cases, 26 were affected by ophthalmological disorders, three had cancer, nine had cardiovascular diseases, and the remainder were orthopedic, gastrointestinal, neurological, urological, congenital, and transplant cases. A total of 94 patients were evacuated to Egypt through the Rafah Crossing, while another 29 reached Jordan through the Kerem Shalom Crossing. Men represented 71 per cent of all evacuees, followed by children (32 per cent) and women (29 per cent).

- Since the ceasefire in October 2025 and up to 16 February 2026, an additional 853 people have reportedly acquired new disabilities. This includes 496 new amputations, 186 spinal cord injuries, and 171 traumatic brain injuries. Despite rising needs, assistive products, including prosthetics, continue to be classified by the Israeli authorities as “dual-use” items, which severely restricts their entry into the Gaza Strip. During this period, only 300 artificial limbs were allowed to enter Gaza under the Health Cluster framework, while the cumulative number of amputations since October 2023 now exceeds 5,000, in addition to the 496 new amputations recorded since the ceasefire.

Water, Sanitation and Hygiene

- Drinking water availability in Gaza city remains severely restricted and well below WASH emergency standards of 6 litres per person per day for thousands of vulnerable families. The principal water supply line, Mekorot north, has been damaged since middle of January, though several repair interventions have taken place, by both Palestinian and Mekorot contractors, there are still issues and currently the control valve is turned off. The next largest fresh water supply for Gaza city, the Safa well field, remains non-operational and WASH actors are requesting access to repair. In the meantime, WASH agencies have increased water trucking from private desalination sources and increased production from groundwater wells, but this does still not meet the needs.

- The relocation of waste from Firas Market in Gaza city to the newly identified temporary dump site in Abu Jarad has resumed after a four-day suspension last week due to security concerns. As of 23 February, approximately 2,500 cubic metres of solid waste had been removed to this temporary dumping site. In addition, the new solid waste generated daily in Gaza city and North Gaza governorates is now being transferred directly to Abu Jarad to prevent further accumulation at Firas Market.

- Between 19 and 24 February, WASH partners distributed 20,000 bars of soap, 11,280 jerrycans, 30,000 bars of soap, 3,850 hygiene kits, and 500 handwashing stations to approximately 3,500 households across the Gaza Strip.

Shelter

- Between 18 and 24 February, Shelter Cluster partners reached 8,836 households with shelter assistance through in-kind and voucher-based modalities. In-kind distributions included 105 tents, 2,439 tarpaulins, 3,905 sealing-off kits, 1,995 bedding kits (each comprising four mattresses, four blankets, six mats and six pillows), 2,000 bedding items, 457 kitchen sets and 1,052 clothing kits and vouchers.

- Some partners reported receiving limited new stock last week, including 31,700 tarpaulins, 16,375 bedding items, and 850 sealing-off kits; however, these quantities remain far below the overall level of need.

- Rejections of timber and plywood sheets continue to hinder the scale‑up of the shelter response and are limiting progress toward transitional and more durable solutions.

Site Management

- Over the past two weeks, Site Management Cluster partners continued the rapid displacement site review that started on 3 February, surveying a total of 900 sites or, 95 per cent of all active ones, to acquire a more in-depth understanding of living conditions and critical sectoral gaps. Findings show:

- Approximately 539 sites (57 per cent) have drainage channels or water paths, while about 606 sites (64 percent) report rainwater accumulation.

- Fire risk remains acute, with 57 per cent of the displaced people living in sites where visible fire hazards are present.

- Shelter conditions are also concerning, with an estimated 2,927 people sleeping outdoors without any form of shelter across roughly 209 sites (22 per cent of those assessed). The sweep highlights critical service shortfalls affecting daily living conditions and dignity.

- In about 199 sites (21 per cent), fewer than half of residents had sufficient drinking water in the last 30 days, and in approximately 227 sites (24 per cent), fewer than half of households had adequate soap to meet basic hygiene needs.

- Access to safe and appropriate energy also remains limited: only 25 sites rely primarily on gas or diesel for cooking, whereas 39 sites primarily burn garbage or plastic, and five sites report no main power source at all, with most others dependent on firewood or agricultural residues.[1]

Protection

- General Protection

- Between 19 and 25 February, 14 partners reached nearly 18,000 people – children, caregivers, women, persons injured and with disabilities, frontline workers, and communities in displacement sites and shelters – with protection related services across Gaza. Mental Health and Psychosocial Support (MHPSS), including Psychological First Aid (PFA), individual and group counselling, and emotional decompression, reached about 9,850 people, while specialized case management and follow‑up reached almost 800 people. More than 130 other people received legal counselling and assistance, while more than 600 people benefitted from 24 protection awareness sessions, and 40 protection committees received capacity-building by cluster partners. During the reporting period, partners also distributed cash-for-protection assistance to 299 households and distributed 2,000 winter clothing kits.

- Protection monitoring was conducted in 24 different neighbourhoods, with 44 focus group discussions and 809 key informant interviews carried out with community members in accessible locations across all governorates. The Protection Cluster also conducted rapid field assessments in two displacement camps in Gaza city and Deir al Balah.

- Child Protection

- Between 19 and 25 February, Child Protection (CP) partners reached approximately 4,700 children and 2,500 caregivers with MHPSS interventions, individual and group psychological counselling, and psychological first aid for children experiencing acute distress.

- Within the above activities, 1,857 caregivers participated in structured parenting and psychosocial support sessions, and an additional 20 caregivers engaged in Teaching Recovery Techniques interventions alongside their children.

- Case management services reached at least 88 children, providing in‑depth assessments, follow‑up, referrals, and home visits for high‑risk cases. A further 150 children received physiotherapy, occupational therapy, speech therapy, medications, and assistive devices based on assessed needs.

- As part of the winter-response effort, 700 children in Khan Younis and Deir al Balah received blankets and clothing kits.

- Capacity‑strengthening efforts continued, with 160 case workers and psychologists completing a four‑day Child Protection Case Management training.

- Throughout the reporting period, CP partners also implemented Ramadan sports and play‑based psychosocial support activities in at least 17 locations across the Gaza Strip. These included football sessions and mini‑leagues, basketball and volleyball for girls, chess competitions, and traditional games. These sports activities were integrated with child protection messaging and psychosocial support, targeting children and adolescents in displacement sites and community spaces. Coordination for league‑style competitions and additional activities is ongoing, with further scale‑up planned throughout Ramadan.

- Addressing Gender-Based Violence (GBV)

- Between 19 and 25 February, partners addressing Gender-Based Violence (GBV) continued providing essential services to more than 18,000 people, primarily through Women and Girls’ Safe Spaces (WGSSs), safe shelters, and Designated Emergency Shelters. The number of WGSS increased from 59 to 68, with newly established locations in Gaza city, Deir al Balah, and Khan Younis. Overall, a total of 24 safe spaces are in Deir al Balah, 22 in Khan Younis, 20 in Gaza city and one in North Gaza and Rafah, respectively. Key services offered include group psychosocial support for women and girls, individual GBV case management with referrals, mental health care provided by psychiatrists, distribution of dignity kits and menstrual hygiene supplies, provision of winter items such as blankets, awareness-raising on GBV risks, and legal aid services.

- Partners are currently reviewing the WGSS guidelines to ensure they reflect the local context as well as global minimum standards for GBV prevention and response. In addition, partners are participating in a capacity‑needs assessment survey that will inform training sessions planned for the next quarter.

- During the reporting period, a GBV Officer participated in a mission to the Rafah Crossing to assess the needs of women and girls. Meanwhile, a GBV partner continued providing psychosocial support and referrals to returnees at the Nasser Hospital protection desk.

- Mine Action

- Between 18 and 24 February, partners conducted seven explosive hazard assessments (EHAs) in support of debris removal activities, including an assessment of a damaged mosque in Deir al Balah on 19 February. Of the assessed locations, only one site was categorized as low risk. UNMAS also carried out independent quality assurance (QA) visits to verify compliance with Standard Operating Procedures (SOPs) and ensure operational standards are consistently upheld, which is an essential component of Mine Action interventions.

- Explosive Ordnance Risk Education (EORE) sessions for civilians continued throughout the reporting period. UNMAS also delivered one EORE training session to eight UN personnel, strengthening their capacity to safely conduct humanitarian operations in high‑risk environments.

- No new explosive ordnance (EO) incidents were recorded during this reporting period. However, backdated data received since the start of the ceasefire indicates 34 EO-related incidents, resulting in 76 victims, including 18 children. Of these casualties, 67 were injured and nine were killed.

Multi-Purpose Cash Assistance (MPCA)

- Between 18 and 24 February, Cash Working Group partners distributed Multi‑Purpose Cash Assistance (MPCA) to more than 3,500 households across the Gaza Strip. Each household received 1,250 Israeli Shekels (US$378) through digital payment modalities in line with the agreed Minimum Expenditure Basket transfer value. In total, more than 165,000 households in Gaza have received at least one MPCA transfer in 2026.

- Market monitoring by the Gaza Market Monitoring Committee indicates continued, although uneven, improvements in commodity inflows. Food markets were generally supplied, and prices for several staple items showed signs of stabilization compared with earlier peaks. However, short‑term price fluctuations continue. The Gaza Consumer Price Index for February, measured up to 22 February, reached approximately 146 per cent of the pre‑October 2023 baseline, showing that overall prices remain significantly elevated despite recent moderation. Availability of non‑food and winter‑related items, such as shelter materials and heating supplies, remains limited and costly, particularly in northern areas.

- Household access to essential goods continues to be constrained primarily by reduced income and purchasing power rather than market availability. Cash‑out services remain functional, with commission fees fluctuating between 12 and 14 percent during the reporting period. Digital payments are the predominant transfer modality, supported by increasing vendor acceptance of e‑wallet transactions. The Cash Working Group continues to monitor financial access conditions closely.

Logistics

- The Logistics Cluster continues to facilitate aid collection and transport services from the platforms of the Kerem Shalom and Zikim crossings. The volume of aid at Gaza crossings has been declining. Over the past week, the Cluster supported partners with the collection and transport of 1,430 pallets from both crossings, representing a 30 per cent decrease compared to the previous reporting period.

- Between 18 and 24 February, Cluster common warehouses across Gaza received 1,414 pallets of aid for storage on behalf of four partners.

- Through Jordan, the Logistics Cluster continues with Back-to-Back (B2B) convoys via both the King Hussein-Allenby and Sheikh Hussein Bridge-Jordan River crossings. Between 18 and 24 February, the Cluster facilitated access to four B2B convoys for three partners with 80 trucks offloaded at Gaza crossings.

- Through Egypt, between 18 and 24 February, only 72 of 244 manifested trucks were offloaded (30 per cent). Return rates have remained high since the closure of Nitzana on 1 January, with recent figures showing persistently low levels of cargo being offloaded at the Gaza crossing.

Emergency Telecommunications

- Since 19 February, the Emergency Telecommunications Cluster (ETC) is deploying technical specialists to Jerusalem to reinforce the secure communications infrastructure supporting the humanitarian response. During the mission, the team has also met with partners to advance planned technical upgrades and ensure alignment with UN telecommunications and information security standards.

- In parallel, the ETC is facilitating pre‑clearance, installation, and deployment of a data‑connectivity solution aimed at providing reliable, shared internet services for humanitarian responders operating in Gaza.

* All figures solely refer to UN and partner assistance dispatched through the UN-coordinated system and are preliminary. Supplies entering through bilateral donations and the commercial sector are not reflected.

[1]Figures should be treated as indicative estimates of conditions across the sites assessed to date, rather than finalized results.

27 February 2026

You must be logged in to post a comment.